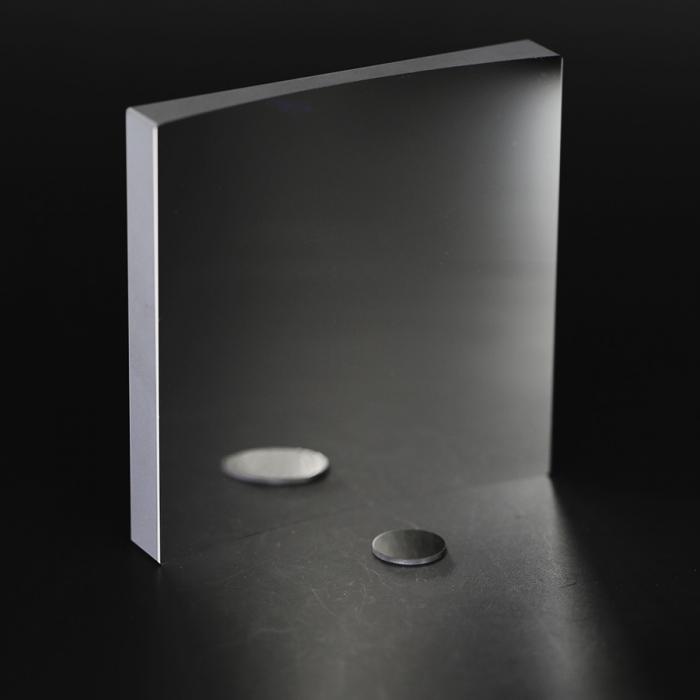

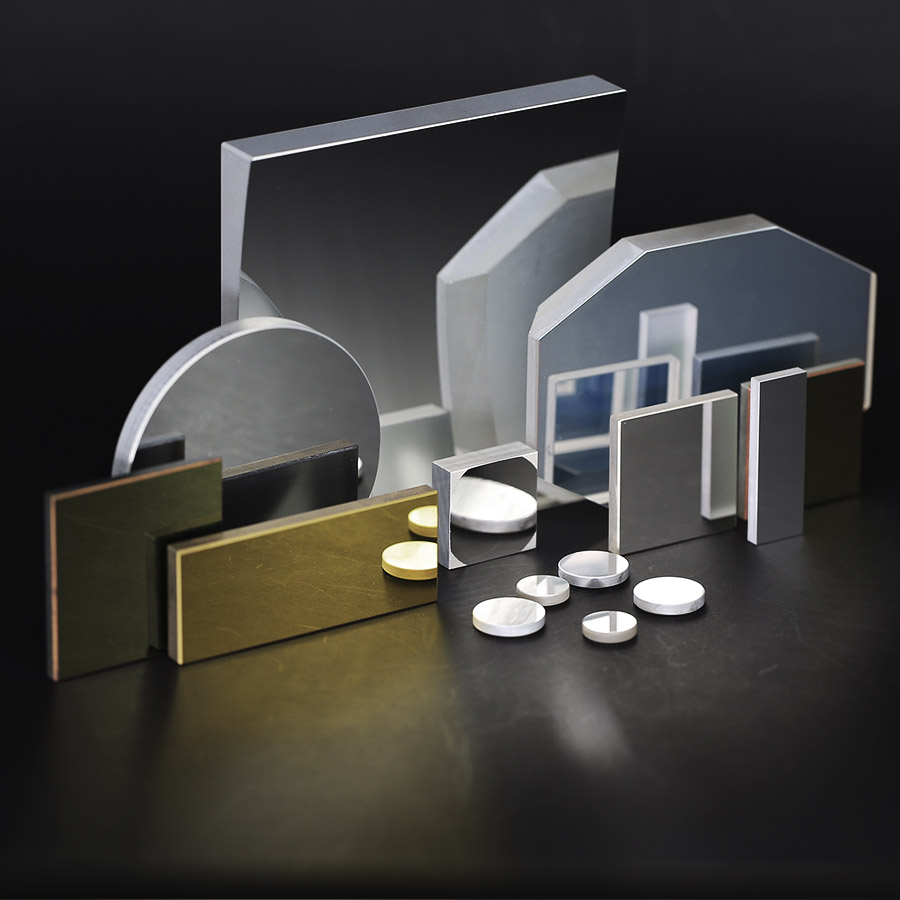

| Name: | Optical Mirrors Optical Reflection Windows |

| Substrate:: | Bk7/ Quartz/ Sapphire/ ZnSe/ Ge |

| Dimensions:: | From 1 mm to 305 mm in any optical axis |

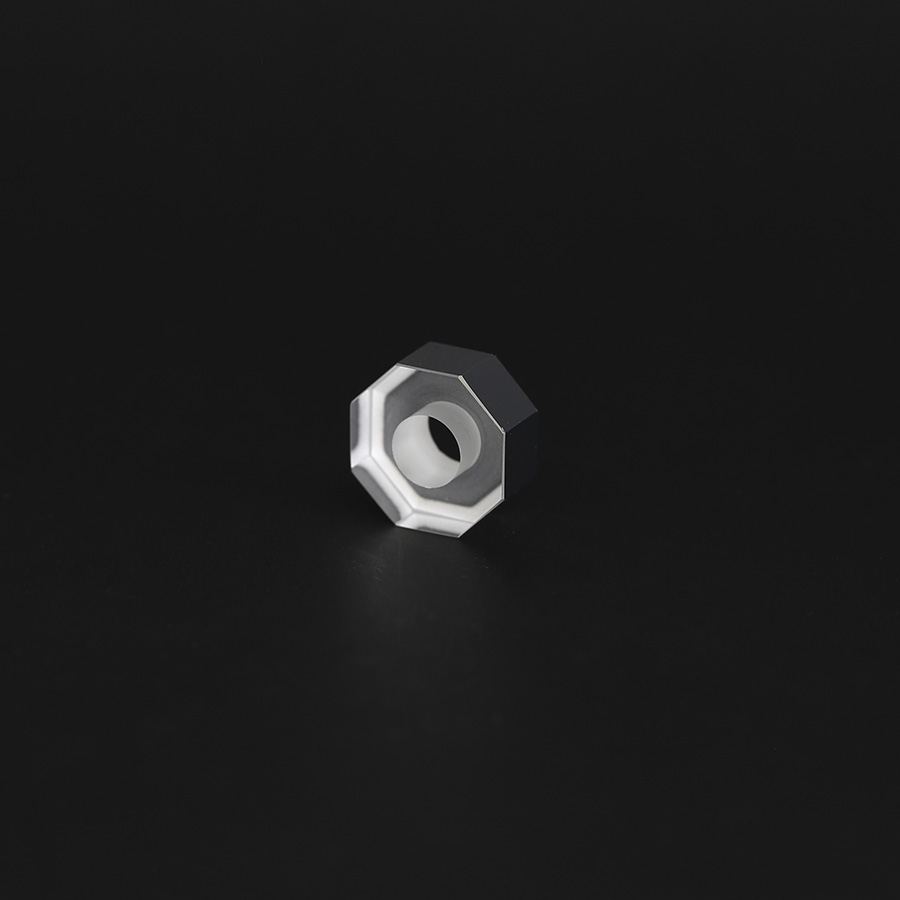

| Shape:: | Flat/ Concave/ Convex/ Dome/ETC |

| Surface Quality:: | S/D 80/40~ 20/10 Per MIL-PRT-13830 |

| Surface Flatness:: | Best As λ/10 @633nm |

| C.A:: | Better Than 90 Over Diameter |

| Tolerance:: | Up To ±0.05mm |

Product Description

Optical Metal Reflector

Optical Mirrors are designed to reflect light for a variety of applications including beam shifting, interferometry, imaging or illumination. Optical Mirrors are used in various industries such as life sciences, metrology, semiconductor or solar. Generally speaking, according to the shape of optical mirrors, they can be divided into spherical mirrors, flat mirrors, and aspheric mirrors. According to the degree of reflection, it is divided into total reflection mirror and half-transmission mirror (beam splitter). According to the reflective coating material, it can be divided into aluminum, silver, gold and high reflective film. The standard manufacturing process is to coat a highly polished substrate material. The performance of the optical mirror produced will be different depending on the materials and processes used for the substrate material and the coating. Because the reflection of light has no effects with the frequency of light, the operating bandwidth of optical mirrors is particularly wide, spanning visible light-ultraviolet-infrared.

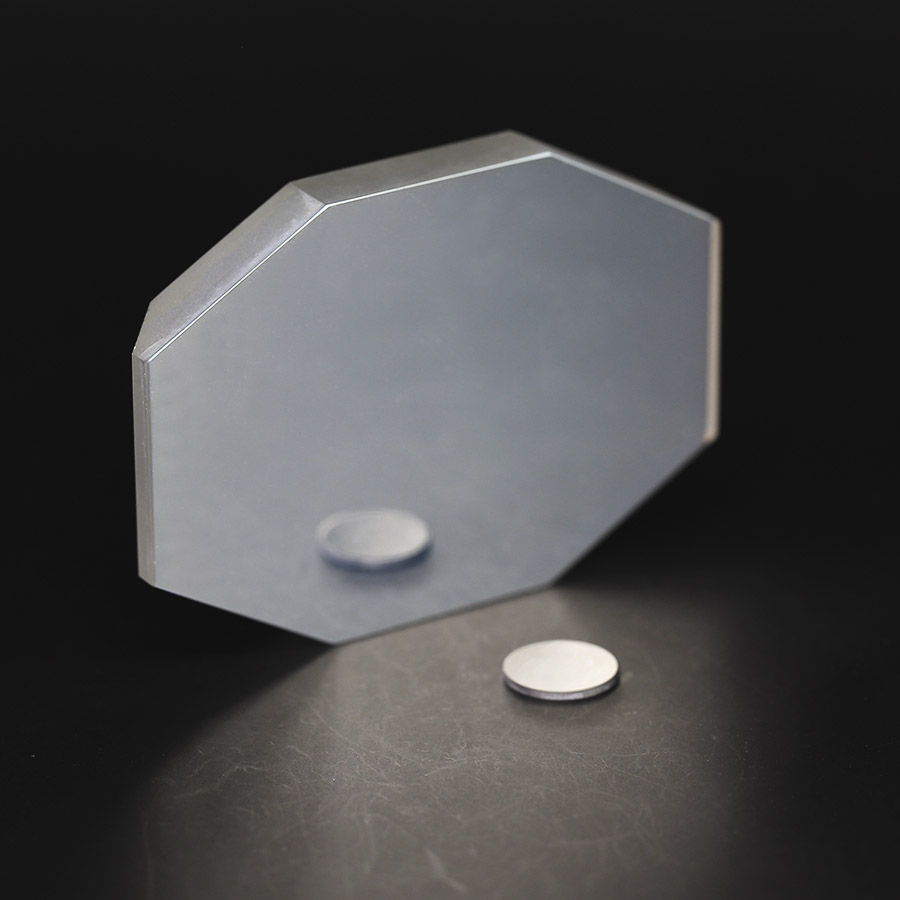

1. Silver-plated reflector

The silver-plated mirror mainly refers to the reflection of light of a certain wavelength required by specific customers to achieve special effects. Application of silver-coated mirrors: In the visible light to near-infrared spectral range, silver-coated mirrors are metal film mirrors with the highest reflectivity, and also provide high reflectivity in the infrared band. To prevent silver oxidation, these mirrors are coated with a durable SiO2 coating approximately 100nm thick. Although the protective layer can prevent silver oxidation, it cannot be used in high humidity environment. These mirrors are ideal for femtosecond pulsed lasers due to their high reflectivity in the 450nm to 20µm range.

Features of silver-coated mirrors

Silver-coated mirrors are a kind of metal-coated mirrors. They have relatively good reflectivity from visible light to infrared bands. Compared with aluminum-coated mirrors, silver-coated mirrors have higher reflectivity. Compared with the all-dielectric mirror, the reflectivity of the silver-coated mirror has little response to the incident angle, and can be used for various incident angles.

2. Aluminized reflector

Aluminum-coated mirrors are less likely to tarnish in high humidity environments than silver-coated mirrors, and offer reflectivity very close to that of unprotected aluminum coatings. These mirrors have an average reflectance of greater than 90% over the 450 nm to 2 µm wavelength range and greater than 95% average reflectance over the 2 to 20 µm wavelength range. Aluminum film mirrors include bare aluminum film mirrors and protective aluminum film mirrors. The protective aluminum film mirrors are coated with a layer of MgF2 or SiO2 on the aluminum film to protect the aluminum film from scratches and oxidation.

Features of aluminized mirrors:

· Flat reflection characteristic curve, wide wavelength range, high reflectivity, cheap price

. The reflectivity is less affected by the change of wavelength and incident angle

. The mechanical hardness of the film surface is not high, and the protective aluminum film (Al+MgF2) can be cleaned with a cotton swab containing organic solvents, but the pure aluminum film (ordinary aluminum film) is relatively soft and cannot be wiped, and needs to be replaced regularly

· Not suitable for strong laser

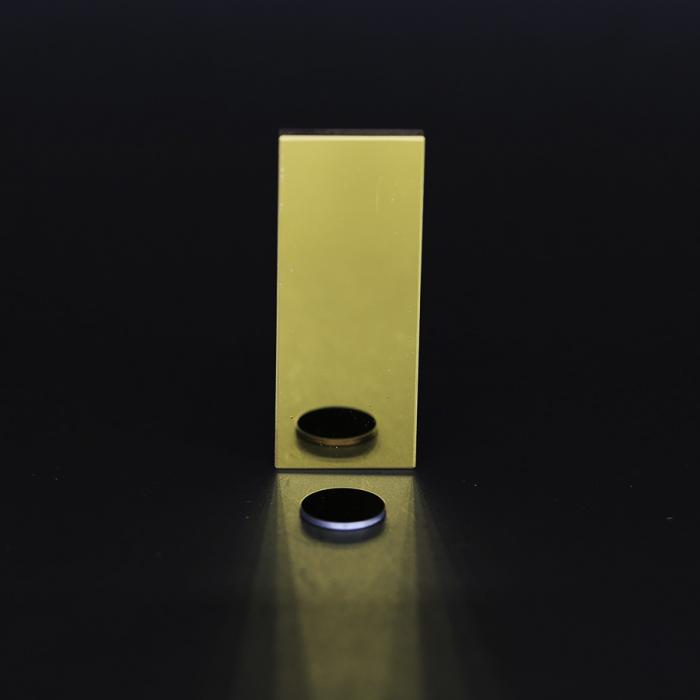

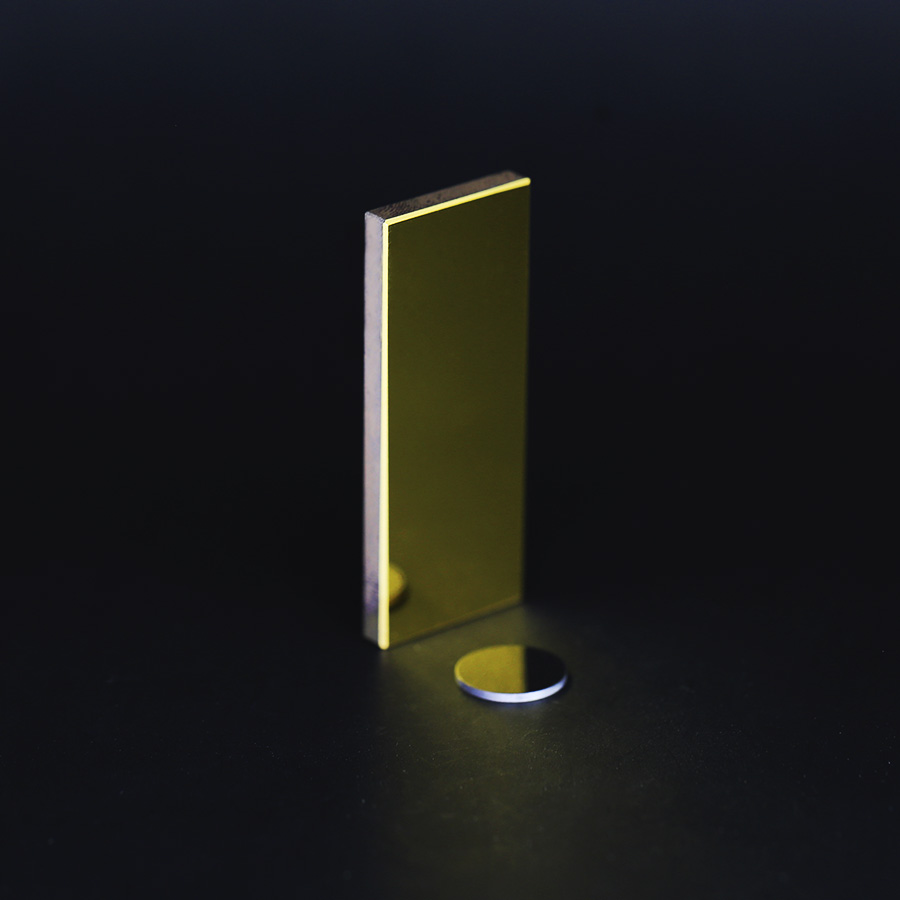

3. Gold Reflective Window Film

The strength and stability of the gold film are better than other metals. The gold-plated reflector has a high reflectivity and is often used as an infrared reflector. Gold-coated mirrors have a high fractional reflectivity in the near-infrared, and the average reflectivity Ravg>96% in the range of 800-2000um. Since the gold film is relatively soft and easy to scratch, the outermost layer of these mirrors is coated with There is a 100nm thick SiO2 film. The gold-coated edge window can be directly soldered or attached to the optomechanical device to seal the two. Gold film windows are widely used in infrared imaging systems and medical equipment.

Features of gold-plated mirrors:

. High reflectivity in the near-infrared band

. The outermost layer is coated with SiO2 protective layer to prevent oxidation and increase strength

. Square or round lenses can be customized

4. High reflective film

Can reflect most of the incident light energy back. When the dielectric film stack is selected, because the loss of the optical film is extremely low, as the number of film layers continues to increase, its reflectivity can continue to increase (close to 100%). Such highly reflective coatings are essential both in the manufacture of lasers and in laser applications.

Optic-Well Welcome You To Inquiry Us Any Time.